Otto Keller GmbH & Co. KG

Das Familienunternehmen der Otto Keller GmbH & Co. KG fertigt hochwertige daunen- und federngefüllte Bettwaren. Der Erfolg unserer klassischen Decken und Kopfkissen basiert auf der Verbindung modernster Maschinen und verantwortungsvoller Manufakturkompetenz. Seit mehr als 70 Jahren steht der Name der Otto Keller GmbH & Co. KG für beste Qualität „Made in Germany“.

Die Bettfedernfabrik wurde 1946 von dem Ingenieur Otto Keller und seiner Ehefrau Elisabeth gegründet. 1982 übernahm Gerhard Wienker das Unternehmen Otto Keller. Unter seiner Leitung hat sich die Otto Keller GmbH & Co. KG als eine der führenden Bettfedernfabriken auf dem europäischen Markt etabliert. Seit 2022 führt Nils Wienker als 3. Generation die Firma weiter.

Bei unseren Bettdecken und Kopfkissen setzen wir, die Otto Keller GmbH & Co. KG, besonderen Wert auf eine ökologische und tierfreundliche Herstellung: Zum Einen verwenden wir Baumwolle aus nachhaltigem Anbau. Hinzu kommt, dass wir eine artgerechte Tierhaltung der Gänse und Enten, die uns ihr Daunenkleid schenken, als unbedingte Tatsache verstehen. Dafür arbeiten wir nach den strengen Downpass-Standards: Die Otto Keller GmbH & Co. KG unterzieht sich regelmäßig der Prüfung der verwendeten Daunen. Diese stammen immer aus artgerechter Tierhaltung, niemals aus dem Lebendrupf oder dergleichen. Unsere Daunenbettwaren sind hochwertige Naturprodukte. Unseren Strom gewinnen wir dabei aus einer eigenen Solaranlage. Diesen hohen tier- und umweltfreundlichen Ansatz verfolgen wir mit absoluter Konsequenz.

Unsere Mitarbeiter

Automatisierte Mehrrohr-Füllmaschine für Bettdecken

Von der Daune zur Decke bei Otto Keller

Unser Herstellungsprozess beginnt mit der Aufbereitung der Rohware. Von deren Wäsche und Trocknung bis hin zur Sortierung der füllfertigen Daunen und Federn werden alle Veredelungsschritte von erfahrenen Fachkräften und modernsten Maschinen ausgeführt. Um eine gleichbleibend hohe Otto Keller-Qualität zu gewährleisten, wird die sogenannte Halbfertigware zunächst gründlich vermischt und daraufhin in Füllmaschinen befördert, die sie auf hochwertige Baumwollhüllen verteilen. Nach der Befüllung wird in jedes Produkt ein kundenspezifisches Etikett bei der Otto Keller GmbH & Co. KG eingenäht. Unsere sorgfältige Qualitätskontrolle garantiert, dass nur erstklassige Bettwaren das Werk verlassen.

Automatisierte Mehrrohr-Füllmaschine für Bettdecken

Von der Daune zur Decke bei Otto Keller

Unser Herstellungsprozess beginnt mit der Aufbereitung der Rohware. Von deren Wäsche und Trocknung bis hin zur Sortierung der füllfertigen Daunen und Federn werden alle Veredelungsschritte von erfahrenen Fachkräften und modernsten Maschinen ausgeführt. Um eine gleichbleibend hohe Otto Keller-Qualität zu gewährleisten, wird die sogenannte Halbfertigware zunächst gründlich vermischt und daraufhin in Füllmaschinen befördert, die sie auf hochwertige Baumwollhüllen verteilen. Nach der Befüllung wird in jedes Produkt ein kundenspezifisches Etikett bei der Otto Keller GmbH & Co. KG eingenäht. Unsere sorgfältige Qualitätskontrolle garantiert, dass nur erstklassige Bettwaren das Werk verlassen.

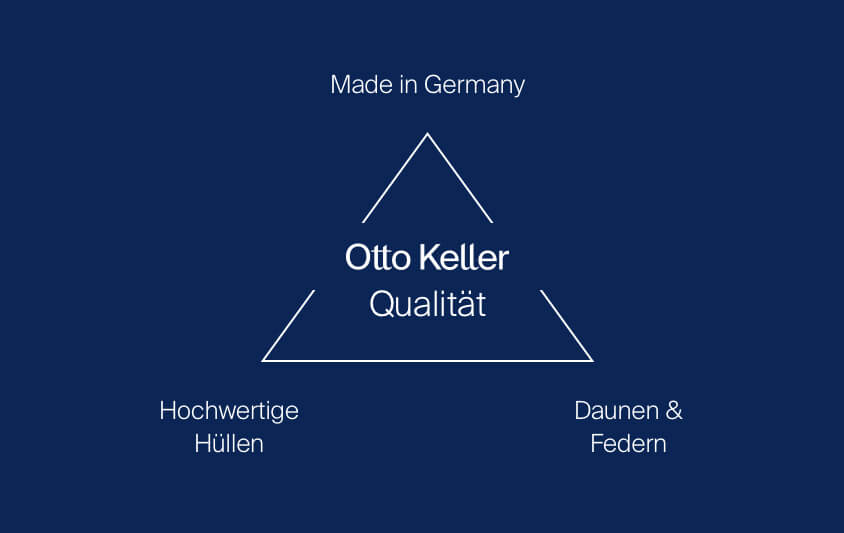

Qualität „Made in Germany“

Die Herstellung unserer Bettwaren der Otto Keller GmbH & Co. KG erfolgt ausschließlich im westfälischen Altenberge. Neben der Veredelung von Daunen und Federn sowie der Konfektion von Bettdecken und Kopfkissen finden hier auch all unsere logistischen Prozesse statt. In modernsten Lagerhallen bearbeiten wir bei Otto Keller täglich eine Vielzahl von Bestellungen, deren Großteil noch am selben Tag europaweit ausgeliefert wird. Eine firmeneigene Näherei erlaubt uns die flexible Umsetzung kundenspezifischer Sonderwünsche, wie besonderer Größen, Farben, Formen oder Füllungen.

Produktionsstandort im westfälischen Altenberge

Qualität „Made in Germany“

Die Herstellung unserer Bettwaren der Otto Keller GmbH & Co. KG erfolgt ausschließlich im westfälischen Altenberge. Neben der Veredelung von Daunen und Federn sowie der Konfektion von Bettdecken und Kopfkissen finden hier auch all unsere logistischen Prozesse statt. In modernsten Lagerhallen bearbeiten wir bei Otto Keller täglich eine Vielzahl von Bestellungen, deren Großteil noch am selben Tag europaweit ausgeliefert wird. Eine firmeneigene Näherei erlaubt uns die flexible Umsetzung kundenspezifischer Sonderwünsche, wie besonderer Größen, Farben, Formen oder Füllungen.

Produktionsstandort im westfälischen Altenberge

„Wir sind stolz auf das perfekte Zusammenspiel aus Moderne und Tradition, aus Mitarbeitern und Maschinen.“

Geschäftsführer Gerhard Wienker

Unser Produktionsprozess

Erholsamer Schlaf ist unsere oberste Priorität bei der Otto Keller GmbH & Co. KG. Um die besten Schlafbedingungen zu schaffen, fertigen wir unsere Bettdecken und Kopfkissen individuell nach Kundenwunsch. Auf Basis konstant hoher Qualitätsstandards und Kontrollen können wir unseren Kunden versichern, dass alle Artikel, die unser Haus verlassen, erstklassig sind. Damit wir sie schnellstmöglich ausliefern können, optimieren wir kontinuierlich unsere logistische Leistungsfähigkeit.

Einkauf

Qualitätskontrollen

Um sicherzustellen, dass nur einwandfreie Daunen und Federn in unsere Bettwaren gelangt, wird jede angelieferte Charge vor Produktionsstart sorgfältig geprüft. Zudem überwachen wir die laufende Produktion mittels kontinuierlicher Stichproben. Die Abschlusskontrolle der fertigen Bettwaren erfolgt vor Ort, in den jeweiligen Produktionsabteilungen. Regelmäßige Prüfungen durch unabhängige Institute bestätigen die gleichbleibende Güte unserer Produkte.

Labor

Um sicherzustellen, dass nur einwandfreie Daunen und Federn in unsere Bettwaren gelangt, wird jede angelieferte Charge vor Produktionsstart sorgfältig geprüft. Zudem überwachen wir die laufende Produktion mittels kontinuierlicher Stichproben. Die Abschlusskontrolle der fertigen Bettwaren erfolgt vor Ort, in den jeweiligen Otto Keller-Produktionsabteilungen. Regelmäßige Prüfungen durch unabhängige Institute bestätigen die gleichbleibende Güte unserer Produkte.

Waschen und Trocknen

Nach Freigabe der angelieferten Daunen und Federn folgt als erster Produktionsschritt die Rohfedernwäsche, für die wir biologisch abbaubare Spezialseifen verwenden. Die anschließende Trocknung bei über 100°C sichert zusätzlich ab, dass unsere Füllware hygienisch einwandfrei ist.

Sortieren

Die frisch gewaschenen Daunen und Federn werden von einer Mehrkammeranlage im Luftstromverfahren sortiert. Je nach Kundenwunsch lassen sich hierbei verschiedenste Qualitätsstufen einstellen.

Mischen

Um für verschiedene Lieferparteien eine gleichbleibende Füllkraft und Qualität sicherzustellen, werden die Daunen und Federn vor ihrer Verfüllung aufgelockert und gründlich vermischt.

Füllen

Während die veredelte, fertig sortierte Füllware auf verschiedene Silos verteilt wird, legen wir Hüllen in der jeweils passenden Steppung bereit. Die Konfektion unserer Bettwaren erfolgt mit Hilfe spezieller Mehrrohranlagen oder manueller Füllautomaten.

Nähen

In unserer eigenen Näherei bearbeiten wir individuelle Kundenwünsche, fertigen beispielsweise Sondergrößen nach Maß. Zudem werden hier sortimentseigene Etiketten und Qualitäts-Zeichen angebracht.

Verpacken und Versand

Ein Großteil unserer Sortimentsartikel ist als Lagerware sofort versandbereit (Drop-Shipping). Dank flexibler Produktionsmöglichkeiten können wir zu fertigende Artikel innerhalb eines Tages verpacken und versenden.

Unsere Philosphie

Mit dem Wissen, dass es sich bei der täglichen Nachtruhe um nichts geringeres als ein menschliches Grundbedürfnis handelt und Schlafkomfort mehr Lebensqualität bedeutet, gehen wir unsere Arbeit besonders gewissenhaft an. Ziel ist es, die Zufriedenheit unserer Kunden kontinuierlich und nachhaltig zu verbessern. Deshalb produzieren wir auf höchstem Niveau und praktizieren einen offenen, fairen Kommunikationsstil – mit unseren Kunden, Mitarbeitern und Lieferanten.

Die Otto Keller-Qualität

Nachhaltigkeit im Unternehmen

Lebensqualität

Unsere Verbände

VDFI e.V.

Der Verband der Deutschen Daunen- und Federnindustrie ist ein Zusammenschluss industrieller Anbieter von daunen- und federngefüllten Bettwaren und Teil des Europäischen Daunen- und Federnverbands (EDFA). Mehr Informationen unter www.vdfi.de.

EDFA e.V.

Im europäischen Verband European Down and Feather Association sind zurzeit mehr als 90 Unternehmen und nationale Verbände aus 23 Ländern organisiert. Verbandsaufgabe ist es, die Interessen seiner Mitglieder in Europa nachhaltig zu vertreten. Mehr Informationen unter www.edfa.eu.

Traumpass e.V.

Als zertifiziertes Mitglied des Traumpass e.V. dürfen wir dessen Siegel Traumpass und DOWNPASS einsetzen. Sie bestätigen, dass unser Unternehmen die vom Verein verlangten Qualitätsansprüche erfüllt, dazu regelmäßig auditiert wird, und dass die Rückverfolgbarkeit der von uns verwendeten Daunen und Federn stets gewährleistet ist. Mehr Informationen unter www.traumpass.com und www.downpass.com

VDFI e.V.

Der Verband der Deutschen Daunen- und Federnindustrie ist ein Zusammenschluss industrieller Anbieter von daunen- und federngefüllten Bettwaren und Teil des Europäischen Daunen- und Federnverbands (EDFA). Mehr Informationen unter www.vdfi.de.

Traumpass e.V.

Als zertifiziertes Mitglied des Traumpass e.V. dürfen wir dessen Siegel Traumpass und DOWNPASS einsetzen. Sie bestätigen, dass unser Unternehmen die vom Verein verlangten Qualitätsansprüche erfüllt, dazu regelmäßig auditiert wird, und dass die Rückverfolgbarkeit der von uns verwendeten Daunen und Federn stets gewährleistet ist. Mehr Informationen unter www.traumpass.com und www.downpass.com

EDFA e.V.

Im europäischen Verband European Down and Feather Association sind zurzeit mehr als 90 Unternehmen und nationale Verbände aus 23 Ländern organisiert. Verbandsaufgabe ist es, die Interessen seiner Mitglieder in Europa nachhaltig zu vertreten. Mehr Informationen unter www.edfa.eu.

Ihr Ansprechpartner

Wir stehen Ihnen telefonisch von Mo-Fr 8.00 Uhr bis 16.30 Uhr zur Verfügung und beantworten Ihnen gerne Ihre Fragen

T +49 (0) 2505 9337-0

F +49 (0) 2505 9337-77

M info@otto-keller.de